Predetermined Overhead Rate POHR: Formula and Calculation

Process costing, on the other hand, is suited for businesses that produce large quantities of homogeneous products. Choosing the right base ensures accurate cost allocation and better decision-making. Further examination of this methodology will delve into its integration with broader cost management strategies and its foundational role in fostering a competitive advantage through precise financial intelligence. The calculation of the plantwide overhead rate first requires gathering the following information. It only takes a minute to calculate your overhead rate, but knowing where your business shines and where it needs improvement allows you to make the changes needed to obtain a healthier bottom line.

D. Percentage of Direct Material Cost

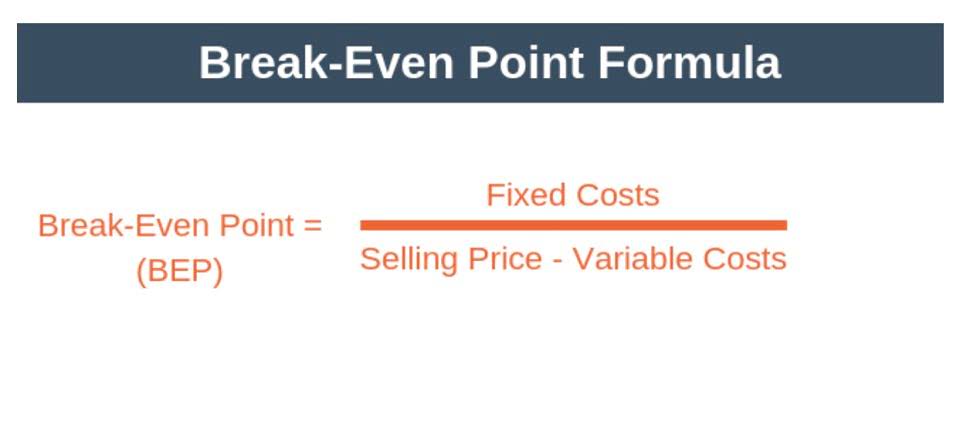

The predetermined overhead rate formula can be used to balance expenses with production costs and sales. For businesses in manufacturing, establishing and monitoring an overhead rate can help keep expenses proportional to production volumes and sales. It can help manufacturers know when to review their spending more closely, in order to protect their business’s profit margins. If your overhead is influenced by predetermined overhead rate formula multiple drivers for instance, some products use more machine time, others more labor a single POR may give inaccurate costs. This is especially useful for businesses with diverse products or services, or when making critical pricing and make-or-buy decisions.

Overhead Rate Meaning, Formula, Calculations, Uses, Examples

Predetermined overhead rate calculation is crucial for setting accurate pricing. It ensures that all manufacturing overhead costs are included, maintaining profitability. The ABC method involves identifying and assigning overhead costs to specific activities that are required to produce goods or services. It then divides the total overhead costs for each activity by the corresponding activity volume to derive the predetermined overhead rate for that activity.

Interesting Facts About Predetermined Overhead Rates

- This means that for every hour of work the marketing agency performs, it will incur $20 in overhead costs.

- You’ll master the key formulas, learn how to allocate costs properly across departments, see real-world examples, and discover best practices to control overhead expenses.

- We can calculate predetermined overhead for material using units to be allocated.

- It encompasses everything that’s necessary to keep the factory running, but isn’t directly tied to the physical components or labor that go into each item.

- It recognizes that overhead costs are not always driven by a single, volume-based activity like direct labor hours or machine hours.

- Hence, preliminary, company A could be the winner of the auction even though the labor hour used by company B is less, and units produced more only because its overhead rate is more than that of company A.

- For example, the activity base for a production department might be the number of production hours.

Calculating predetermined overhead rates is crucial for accurately assessing production costs. Sourcetable simplifies this process through its AI-powered spreadsheet capabilities. By inputting basic cost drivers and total estimated overhead costs—factors such as Direct Labor Hours or Machine Hours—the AI assistant processes data instantly. This functionality is indispensable for retained earnings finance professionals and students keen on precision and efficiency.

- Consequently, it provides rates companies can apply to every product or service produced.

- This calculation acts as a tool for timely reviews of spending, helping to trigger necessary adjustments in expense management in relation to changes in production or sales.

- Understanding these variances provides crucial feedback for refining future overhead rate calculations, budgeting processes, and operational strategies.

- The necessity for this periodicity arises from the inherent dynamism of operational costs and production volumes.

- The number of units produced allocates overhead costs based on the number of units manufactured.

- It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount).

- The production manager has told us that the manufacturing overhead will be $ 500,000 for the whole year and the company expected to spend 20,000 hours on direct labor.

- Underapplied overhead occurs when actual overhead exceeds applied overhead, resulting in undercosted products.

- You would then take the measurement of what goes into production for the same period.

- By understanding the components of manufacturing overhead, identifying relevant cost drivers, and utilizing cost pools, businesses can gain greater control over their production costs.

- Its accurate determination is paramount, as any significant deviation from actual costs can lead to material misstatements in product costing, inventory valuation, and ultimately, profitability analysis.

- It suggests they are more efficient at managing their indirect costs relative to their production, allowing them to bake less overhead into their bids while still hitting their profit targets.

If you’re running several warehouses, calculate separate rates for each location. The rent in Atlanta isn’t the same as Chicago, and your overhead rate should reflect that. The elimination of difference between applied overhead and actual overhead is known as “disposition of over or under-applied overhead”. While it might not be as automated as dedicated accounting software, it offers a cost-effective solution for small to medium-sized businesses, or for specific tasks within larger organizations. Review historical data, consider any planned changes in production or costs, and use realistic assumptions when making your estimations. The important takeaway is that these costs are essential for production, but can’t be easily traced to individual products.

This overhead allocation method finds its place in very small entities with a minimized or simple cost structure. A predetermined overhead rate is used to allocate overhead costs to products or services. This allows companies to track the true cost of production and set prices accordingly. Detailed analysis of predetermined overhead rates helps businesses identify the activities or factors that drive overhead costs, enabling targeted cost-reduction Bookkeeping vs. Accounting measures.

Ответить

Want to join the discussion?Feel free to contribute!